| Sign In | Join Free | My portofva.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My portofva.com |

|

Brand Name : XYMJ

Model Number : YG15,YG20

Certification : ISO9001 : 2018

Place of Origin : China

MOQ : Negotiable

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 2000 kilograms per month

Delivery Time : 7-15

Packaging Details : Inner packing: wrapped by bubble bag,foam. Outer packing: standard export carton

Product Name : Tungsten carbide cold roller

Main chemical composition : WC and Co

HRA : 82-92

TRS : 1180-2250 N/mm3

Application : precessing reinforcing steel wires

Process engineer : Adopt advanced technology value

Surface : Customized

Textile Industry Machining Tungsten Carbide Roller Easy Operation Carbide Wire Guide Roller

Description of product

Carbide roller rings

High quality tungsten carbide roll / rollers for rolling mill are widely used as seal faces with resistant-wearing, high fracturing strength, high thermal conductivity, small heat expansion co-efficient. It is the best material to resist heat and fracture in all hard face materials.

Service is to be rendered for the design, grooving machining and rib machining of composite cemented carbide roll rings.

Various compatible tools can be provided for machining composite cemented carbide roll rings.

Grade List

| Grades | Binder (wt %) | WC Grain-Size | Physical Properties | Mechanical Properties | ||||

| Density g/cm3 | Thermal Conductivity W/(M.K) | Average Thermal Expansion Coefficient | HRA | TRS | Compressive Strength | |||

| XY27T | 30 | Extra-Coarse | 12.73 | 60 | 5.8-70-.0 | 79 | 2560 | 2700 |

| XY27 | 30 | Medium-Coarse | 12.65 | 60 | 5.8-7.0 | 79 | 2626 | 2800 |

| XY26 | 27.5 | Medium-Coarse | 12.85 | 65 | 5.6-6.8 | 79.8 | 2653 | 2800 |

| XY28T | 25 | Extra-Coarse | 13 | 70 | 5.5-6.5 | 80.3 | 2750 | 2800 |

| XY28 | 25 | Medium-Coarse | 13.04 | 70 | 5.5-6.5 | 80.8 | 2625 | 3000 |

| XY29 | 22 | Coarse | 13.36 | 70 | 5.5-6.5 | 81.8 | 2840 | 3000 |

| XY30 | 20 | Coarse | 13.48 | 80 | 5.2-6.0 | 82.3 | 2742 | 3200 |

| XY31 | 18 | Coarse | 13.68 | 90 | 5.0-5.8 | 83.3 | 2802 | 3200 |

| XY32 | 16 | Coarse | 13.77 | 90 | 5.0-5.8 | 83.8 | 2872 | 3200 |

| XY32C | 17.5 | Coarse | 13.66 | 90 | 5.0-5.8 | 84.5 | 2872 | 3200 |

| XY33 | 15 | Coarse | 13.98 | 100 | 5.0-5.8 | 84.5 | 2872 | 3200 |

| XY34 | 13 | Coarse | 14.17 | 100 | 4.8-5.6 | 85.5 | 2875 | 3400 |

| XY35 | 10 | Coarse | 14.43 | 100 | 4.8-5.6 | 86.5 | 2753 | 3500 |

| XY36 | 8 | Extra-Coarse | 14.69 | 110 | 4.5-5.4 | 86.8 | 2406 | 4000 |

| XY37 | 6 | Extra-Coarse | 14.87 | 110 | 4.5-5.4 | 87.5 | 2358 | 4100 |

| XY27A | 30 | Medium-Coarse | 12.7 | 60 | 5.8-7.0 | 79.5 | 2780 | 2900 |

| XY28A | 25 | Medium-Coarse | 13.15 | 70 | 5.5-6.5 | 81.2 | 2675 | 3000 |

| XY29A | 22 | Coarse | 13.38 | 70 | 5.5-6.5 | 82.2 | 2750 | 3000 |

| XY30A | 20 | Coarse | 13.5 | 80 | 5.2-6.0 | 84 | 2586 | 3100 |

| XY31A | 18 | Coarse | 13.65 | 90 | 5.5-5.8 | 84 | 2806 | 3100 |

| XY33A | 15 | Coarse | 13.92 | 90 | 5.0-5.8 | 85.5 | 2790 | 3200 |

| XY35A | 10 | Coarse | 14.45 | 100 | 4.8-5.6 | 86.8 | 2456 | 3500 |

| XY36A | 8 | Extra-Coarse | 14.69 | 110 | 4.8-5.6 | 87 | 2460 | 4000 |

| XY37A | 6 | Extra-Coarse | 14.87 | 110 | 4.5-5.5 | 88 | 2386 | 4100 |

| Dimension | ||

| OD | ID | H |

| 140-500mm | 80-300mm | 10-250mm |

| Grade | I | Ⅱ | Ⅲ | Ⅳ | Special request |

| OD | ±0.02 | ±0.05 | ±0.10 | ±0.15 | |

| ID | ±IT5 | ±IT6 | ±IT7 | ±IT8 | |

| H | ±0.015 | ±0.050 | ±0.100 | ±0.25 |

| Name | Dimension | ||

| D | d | H | |

| Two-groove rolls | 180 | 110 | 55 |

| Two-groovecarved rolls | 180 | 110 | 55 |

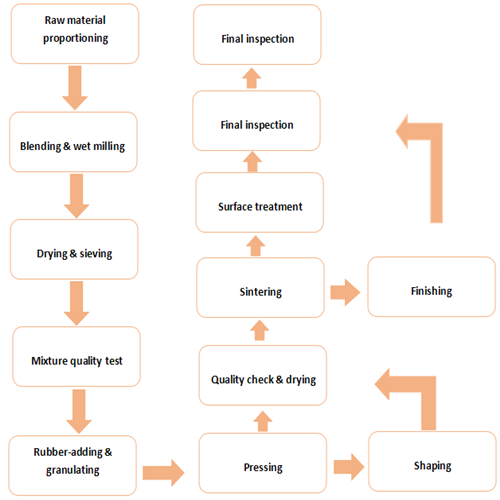

Production Process

FAQ

Q1: How can I place order?

A1: You can contact us by email about your order details, or place order on line.

Q2: How can I pay you?

A2: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

Q3: What’s the order procedure?

A3: First we discuss order details, production details by email or TM. Then we issue you an PI for your confirmation. You will be requested to do pr -epaid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 7-15 days if we don’t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

Q4: How do you take care when your clients received defective products?

A4: replacement. If there are some defective items, we usually credit to our customer or replace in next shipment.

Q5: How do you check all the goods in the production line?

A5: We have spot inspection and finished product inspection. We check the goods when they go into next step production procedure.

|

|

Textile Industry Carbide Wire Guide Rollers Easy Operation For Rolling Mill Images |